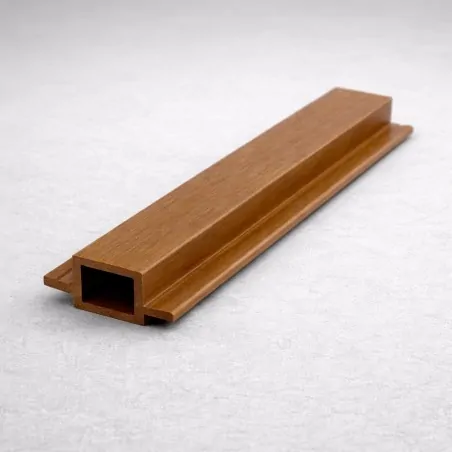

The joist for the cladding with thick cuttings is an essential intermediate stem, with perfectly finished finishes to complete the construction.

It is applied at the end of the investment allowing the placement of the final connector.

![]()

Component Analysis

Environmental Characteristics

Look and feel

Processing Properties

The Strength

Hardware placement TIP!

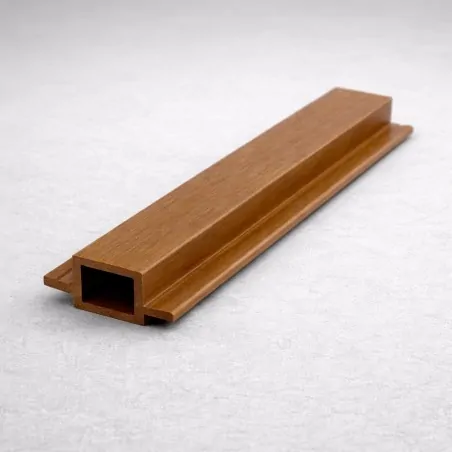

The joist for the cladding with thick cuttings is an essential intermediate stem, with perfectly finished finishes to complete the construction.

It is applied at the end of the investment allowing the placement of the final connector.

![]()

Component Analysis

Environmental Characteristics

Look and feel

Processing Properties

The Strength

Hardware placement TIP!

3D WPC Wall Cladding Slat Panel Coffee Brown 2.5x22x290cm - Co-Extrusion Wood Composite

Single start 3D profile Trim 2,5 x 4,9 x 290cm- brown

L trim for gladding 3D 4,6 x 8,9 x 290cm - brown