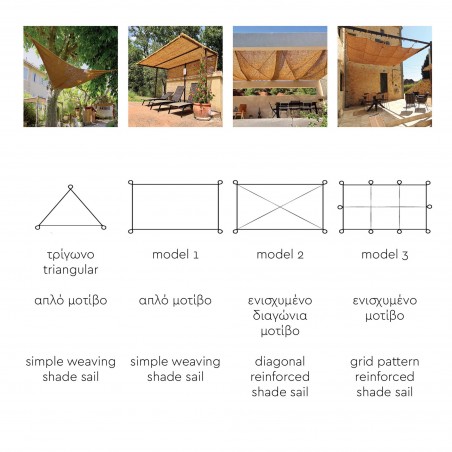

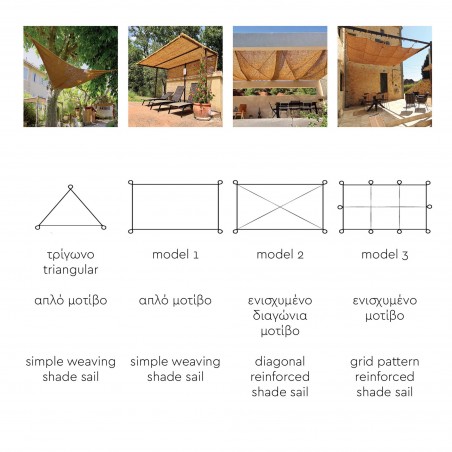

This particular design, made out of coconut fiber, is to be hung with a fixation point every meter and at each corner with the loops. Grid-pattern rope reinforcement.

Installing this shade sail requires heart-shaped thimbles and 10 m of rope Ø 1 cm for the corners.

The shade sail weaving sifts the sun’s rays and is weatherproof, rot-resistant, and sturdy. It allows air to pass through for a fresh and pleasant feeling.

This design requires the installation of one steel heart-shaped thimble per loop, which will strengthen the loop and protect it from friction and wear.

The kit for design N.3 depends on the sail dimension. For each loop, you will need 1 heart-shaped thimble, two plastic cable ties, and some fine rope (to hide the cable tie). An instruction manual is also included.

For this design, you will also need :

– some rope to attach the angle loops

– steel cables

The cable’s length and diameter depend on the distance between the loops and the fixation points. Usually, a cable diameter of 0.5 cm is enough.

Shade sails are 1,2 kg per m2, double in weight when wet. They dry very quickly, thanks to their spaced-out weaving. Coconut fiber becomes slack once wet, and this feature reverts when it dries up; it’s how coconut fiber reacts to the humidity. It may be necessary to slightly stretch your shade sail after the first rains, especially regarding the large sails or when they’re attached with coir rope.

RECOMMENDATION BEFORE PLACING THE SHADE SAIL

We strongly advise you to rinse your sail shades and attachment rope with running water (on gravel or lawn, for example) and then let them dry before installation.

Repeat the operation if necessary.

This will minimize the deterioration that can cause, in some cases, the natural tannins of the coconut fiber.

Coconut fibers, like wood, are a natural material based on cellulose. When exposed to sunlight, it is natural for them to undergo a color change, often turning into a grayish-brown tone. The primary factor causing this fading is the ultraviolet (UV) radiation from the sun, which negatively affects natural fibers, including coconut.

Over time, continuous exposure to UV rays breaks down the pigments that give coconut its brown color, leading to a gradual faded appearance. This process is entirely normal and unavoidable for materials like coconut fibers, which are based on natural substances.

We avoid using chemical dyes or other additives to prevent fading in our products, as we believe in preserving the natural texture and appearance of the materials we use.

This particular design, made out of coconut fiber, is to be hung with a fixation point every meter and at each corner with the loops. Grid-pattern rope reinforcement.

Installing this shade sail requires heart-shaped thimbles and 10 m of rope Ø 1 cm for the corners.

The shade sail weaving sifts the sun’s rays and is weatherproof, rot-resistant, and sturdy. It allows air to pass through for a fresh and pleasant feeling.

This design requires the installation of one steel heart-shaped thimble per loop, which will strengthen the loop and protect it from friction and wear.

The kit for design N.3 depends on the sail dimension. For each loop, you will need 1 heart-shaped thimble, two plastic cable ties, and some fine rope (to hide the cable tie). An instruction manual is also included.

For this design, you will also need :

– some rope to attach the angle loops

– steel cables

The cable’s length and diameter depend on the distance between the loops and the fixation points. Usually, a cable diameter of 0.5 cm is enough.

Shade sails are 1,2 kg per m2, double in weight when wet. They dry very quickly, thanks to their spaced-out weaving. Coconut fiber becomes slack once wet, and this feature reverts when it dries up; it’s how coconut fiber reacts to the humidity. It may be necessary to slightly stretch your shade sail after the first rains, especially regarding the large sails or when they’re attached with coir rope.

RECOMMENDATION BEFORE PLACING THE SHADE SAIL

We strongly advise you to rinse your sail shades and attachment rope with running water (on gravel or lawn, for example) and then let them dry before installation.

Repeat the operation if necessary.

This will minimize the deterioration that can cause, in some cases, the natural tannins of the coconut fiber.

Coconut fibers, like wood, are a natural material based on cellulose. When exposed to sunlight, it is natural for them to undergo a color change, often turning into a grayish-brown tone. The primary factor causing this fading is the ultraviolet (UV) radiation from the sun, which negatively affects natural fibers, including coconut.

Over time, continuous exposure to UV rays breaks down the pigments that give coconut its brown color, leading to a gradual faded appearance. This process is entirely normal and unavoidable for materials like coconut fibers, which are based on natural substances.

We avoid using chemical dyes or other additives to prevent fading in our products, as we believe in preserving the natural texture and appearance of the materials we use.